Infrastructures

Laboratório de Radioesterilização (LR) (Radiosterilization Laboratory) it is a self-sealing source installation, with a semi-industrial dimension, designed to operate 24 hours a day, and can operate in continuous or batch mode. The planar irradiator, containing sources of Cobalt-60, when in the storage position, is below the ground in a dry concrete container, armored with steel blocks. The International Atomic Energy Agency (IAEA) classifies the irradiation chamber in Category I*.

*IAEA Safety Standards, NºSSG-8 Specific Safety: "Radiation Safety of Gamma, Electron and X Ray Irradiation Facilities", Capítulo 3: Types of Irradiator. http://www-ns.iaea.org/standards/

Main Areas

It is divided into two distinct areas:

- Controlled area (Zone 1): irradiation chamber (and access, fenced with net) and control room;

- Supervised area (Zones 2-3): remaining spaces (kitchen, office, workshops and administrative area).

This classification is based on radiation exposure, with Zone 1 being the most exposed (occupational exposure) and Zones 2-3 the least exposed (public and population in general). Both areas are of restricted access (cf. internal procedures) and are duly identified and signed.

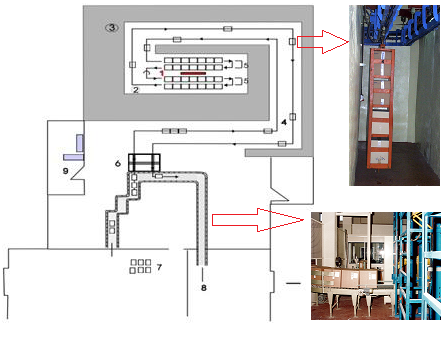

A1 - Cross-section, with the main areas: 1. Irradiator; 2.

Irradiation Chamber; 3. Biological protection walls; 4. Labyrinth room;

5. Irradiation positions; 6. Loading and unloading station; 7. Product

warehouse before irradiation; 8. Product warehouse after irradiation.

Irradiation Chamber

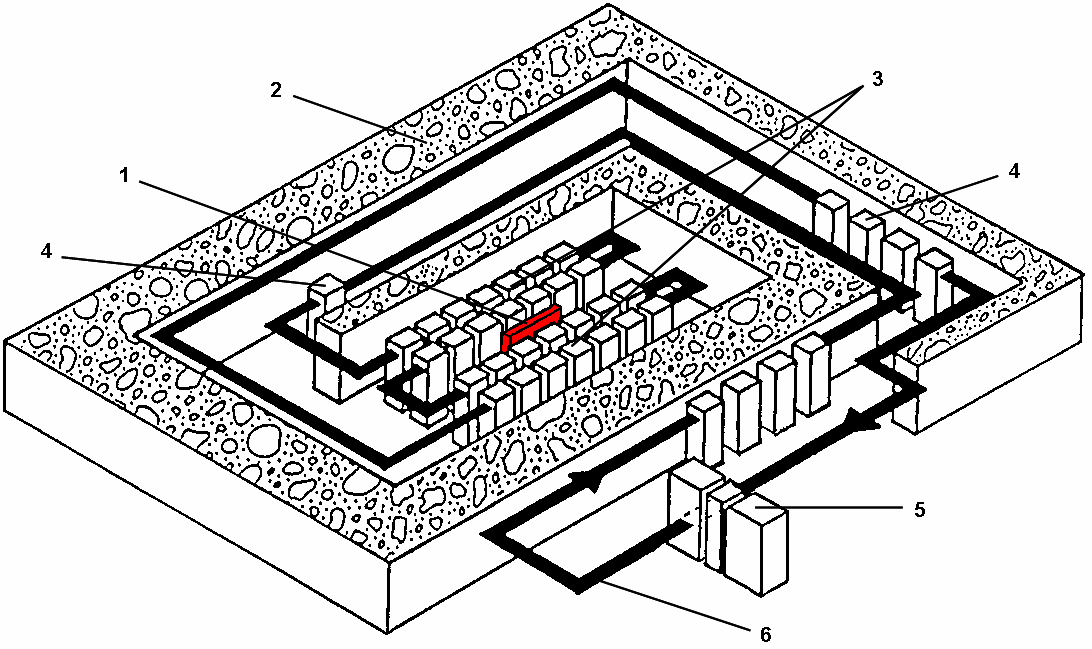

The irradiation chamber includes stainless steel tubes, where sealed sources of Cobalt-60 are found. In the storage position, the radiator is collected in an armored sarcophagus. This biological shield against radiation, also includes a labyrinth with 23.3 meters in length, through which the interior of the irradiation chamber is accessed (see Figure A2). Outside there is a control room, where the operator monitors/controls all processes.

A2 - 3D diagram of the UTR: 1. Planar irradiator; 2. Biological shield; 3. Cycle irradiation positions; 4. Waiting positions; 5. Loading, rearrangement and unloading system; 6. Trajectory of products in irradiation cycle.

Control and Security System

The Control System (automation) has been updated, and consists of:

- supervision system;

- alarm system;

- monitoring/notification system;

- documentation process system.

Lifetime

Lifetime